|

WELDING

SYMBOLS

Special symbols are used on a drawing to specify where

welds are to be located, the type of joint to be used, as well

as the size and amount of weld metal to be deposited in the

joint. These symbols have been standardized by the American

Welding Society (AWS). You will come into contact with these

symbols anytime you do a welding job from a set of blueprints.

You need to have a working knowledge of the basic weld symbols

and the standard location of all the elements of a welding

symbol.

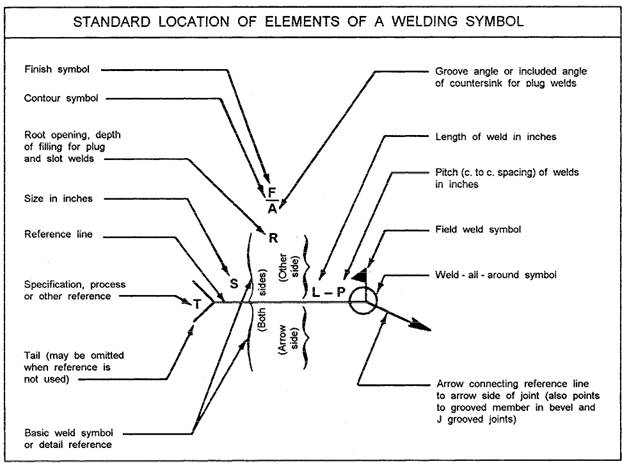

A standard welding symbol (fig. 3-43) consists of a

reference line, an arrow, and a tail. The reference line

becomes the foundation of the welding symbol. It is used to

apply weld symbols, dimensions, and other data to the weld.

The arrow simply connects the reference line to the joint or

area to be welded. The direction of the arrow has no bearing

on the significance of the reference line. The tail of the

welding symbol is used only when necessary to include a

specification, process, or other reference information.

Weld Symbols

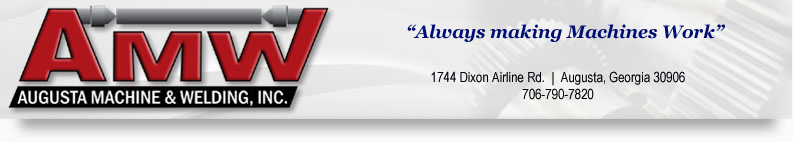

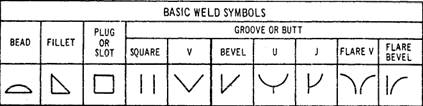

The term weld symbol refers to the symbol for a specific

type of weld. As discussed earlier, fillet, groove, surfacing,

plug, and slot are all types of welds. Basic weld symbols are

shown in figure 3-44. The weld

Figure 3-44.-Basic weld symbols.

Figure 3-45.-Weld symbols applied to reference line.

Figure 3-46.-Specifying weld locations.

Figure 3-47.-Arrowhead indicates beveled plate.

symbol is only part of the information required in the

welding symbol. The term welding symbol refers to the total

symbol, which includes all information needed to specify the

weld(s) required.

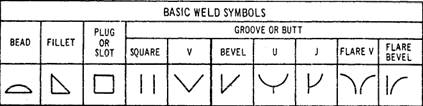

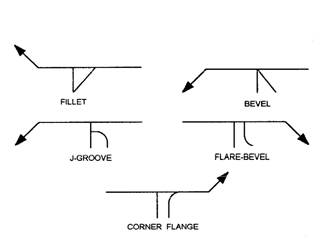

Figure 3-45 shows how a weld symbol is applied to the

reference line. Notice that the vertical leg of the weld

symbol is shown drawn to the left of the slanted leg.

Regardless of whether the symbol is for a fillet, bevel,

J-groove, or flare-bevel weld, the vertical leg is always

drawn to the left.

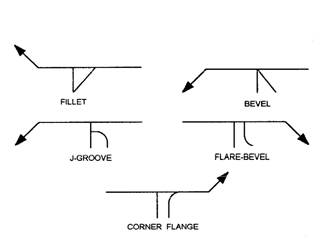

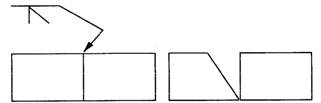

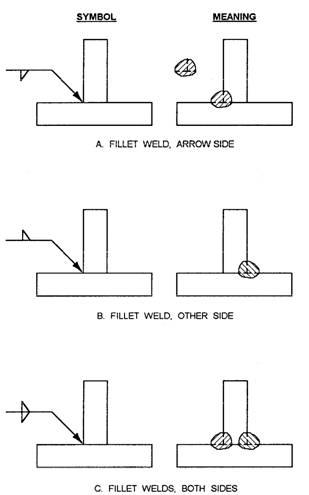

Figure 3-46 shows the significance of the positions of the

weld symbols position on the reference line. In view A the

weld symbol is on the lower side of the reference line that is

termed the arrow side. View B shows a weld symbol on the upper

side of the reference line that is termed the other side. When

weld symbols are placed on both sides of the reference line,

welds must be made on both sides of the joint (view C).

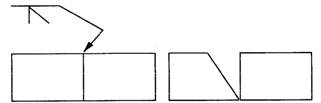

When only one edge of a joint is to be beveled, it is

necessary to show which member is to be beveled. When such a

joint is specified, the arrow of the welding symbol points

with a definite break toward the member to be beveled. This is

shown in figure 3-47.

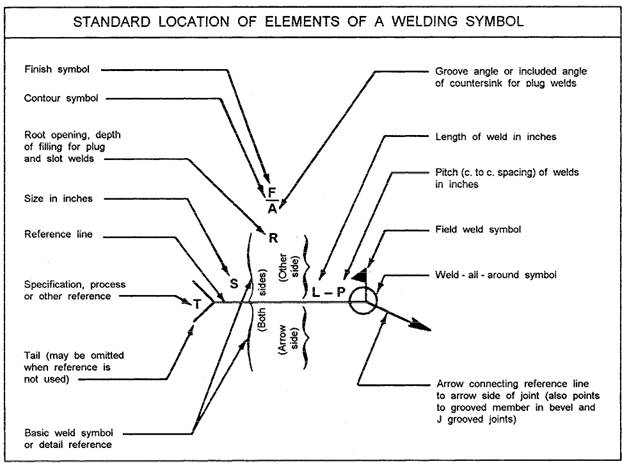

Figure 3-48 shows other elements that may be added to a

welding symbol. The information applied to the reference line

on a welding symbol is read from left to right regardless of

the direction of the arrow.

Dimensioning

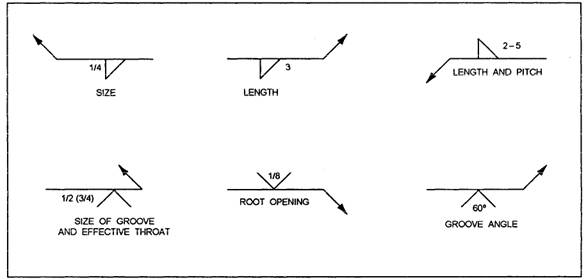

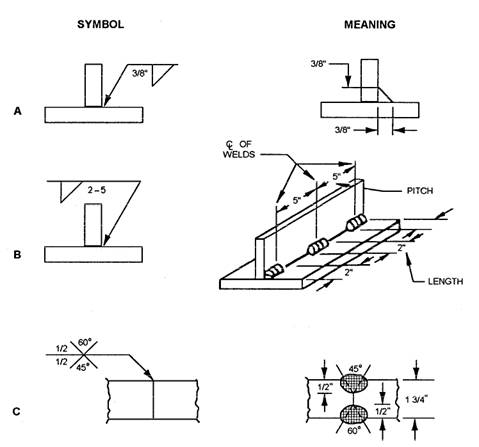

In figure 3-48, notice there are designated locations for

the size, length, pitch (center-to-center spacing), groove

angle, and root opening of a weld. These locations are

determined by the side of the reference line on which the weld

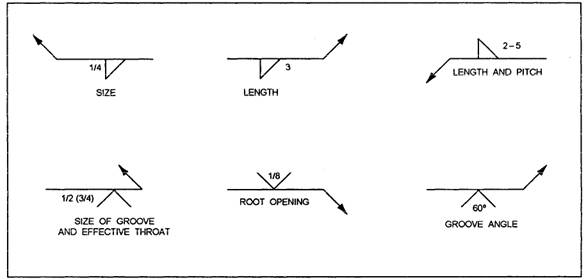

symbol is placed. Figure 3-49 shows how dimensions are applied

to symbols.

Figure 3-48.-Elements of a welding symbol.

Figure 3-49.-Dimensions applied to weld symbols.

Figure 3-50.-Dimensioning of welds.

Figure 3-51.-Supplementary symbols.

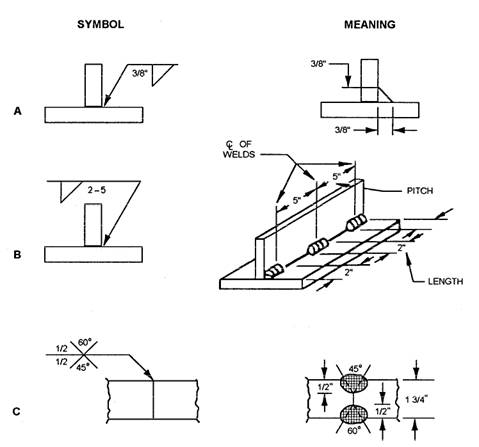

Figure 3-50 shows the meaning of various welding dimension

symbols. Notice that the size of a weld is shown on the left

side of the weld symbol (fig. 3-50, view A). The length and

pitch of a fillet weld are indicated on the right side of the

weld symbol. View B shows a tee joint with 2-inch intermittent

fillet welds that are 5 inches apart, on center. The size of a

groove weld is shown in view C. Both sides are 1/2 inch, but

note that the 60-degree groove is on the other side of the

joint and the 45-degree groove is on the arrow side.

Supplementary Symbols

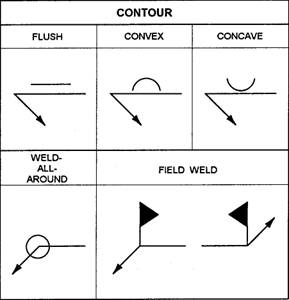

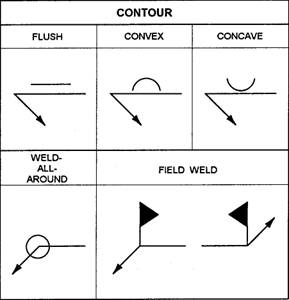

In addition to basic weld symbols, a set of supplementary

symbols may be added to a welding symbol. Some of the most

common supplementary symbols are shown in figure 3-51.

Contour symbols are used with weld symbols to show how the

face of the weld is to be formed. In addition to contour

symbols, finish symbols are used to indicate the method to use

for forming the contour of the weld.

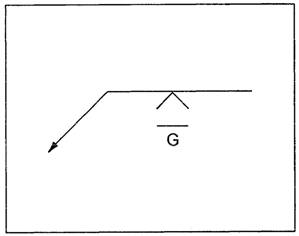

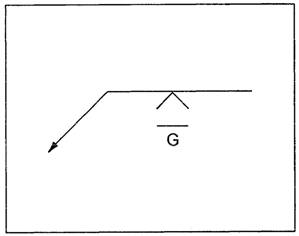

When a finish symbol is used, it shows the method of

finish, not the degree of finish; for example, a C is used to

indicate finish by chipping, an M means machining, and a G

indicates grinding. Figure 3-52 shows how contour and finish

symbols are applied to a welding symbol. This figure shows

that the weld is to be ground flush. Also, notice that the

symbols are placed on the same side of the reference line as

the weld symbol.

Figure 3-52.-Finish and contour symbols.

Figure 3-53.-Specifying additional welding information.

Another supplementary symbol shown in figure 3-51 is the

weld-all-around symbol. When this symbol is placed on a

welding symbol, welds are to continue all around the joint.

Welds that cannot be made in the shop are identified as

field welds. Afield weld symbol is shown in figure 3-51. This

symbol is a black flag that points toward the tail of the

welding symbol.

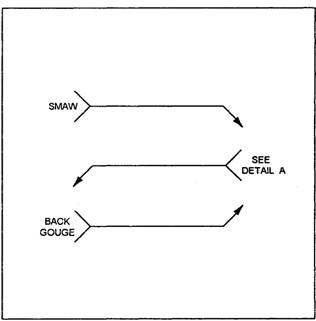

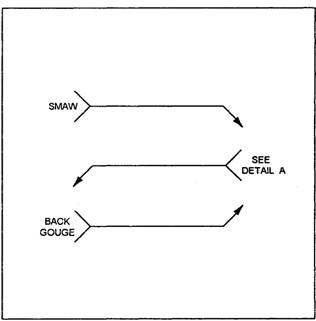

Specifying Additional Information

It is sometimes necessary to specify a certain welding

process, a type of electrode, or some type of reference

necessary to complete a weld. In this case, a note can be

placed in the tail of the reference line. (See

Figure 3-55.-Example of welding symbol in use.

fig. 3-53.) If additional information is not needed, then

the tail is omitted.

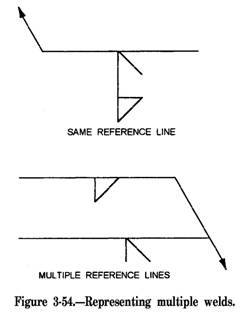

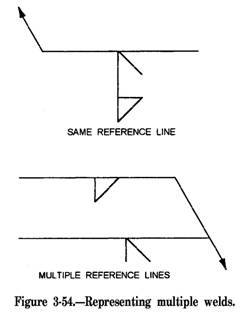

Multiple-Weld Symbols

When you are fabricating a metal part, there are times when

more than one type of weld is needed on the same joint; for

example, a joint may require both a bevel groove weld and a

fillet weld. Two methods of illustrating these weld symbols

are shown in figure 3-54. Note that in each welding symbol,

the bevel groove weld is to be completed first, followed by

the fillet weld.

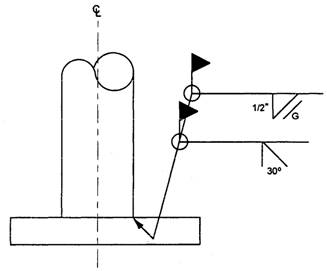

Applying a Welding Symbol

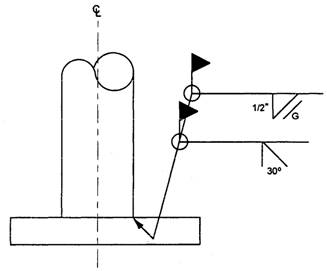

Figure 3-55 shows an example of how a welding symbol may

appear on a drawing. This figure shows a

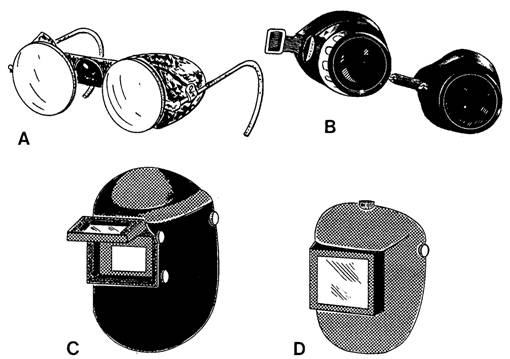

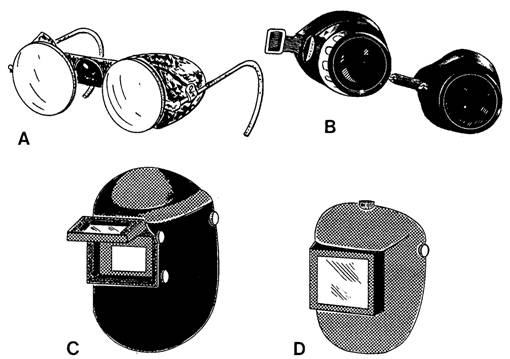

Figure 3-56.-Eye protection devices.

steel pipe column that is to be welded to a baseplate. The

symbol tells the welder that the pipe is to be beveled at a

30-degree angle followed by a bevel groove weld all around the

joint. This is followed by a 1/2-inch fillet weld that is also

welded all around the joint. Finally, finish the fillet weld

by grinding it to a flush contour. As the field weld symbol

indicates, all welds are to be accomplished in the field.

For additional information about welding symbols, refer

to Symbols for Welding and Nondestructive Testing, ANSI/AWS

A2.4-86.

Information

provided by

Tpub.com |